PROJECTS AND WORKS

This section includes all the projects and assignments I’ve done during the course period. The photos and screenshots of the model developement stages are available with the step explaination.

Note: For detailed stepwise explaination on how to use every machines, visit the Tutorial Section

SECTIONAL CONTENTS

ASSIGNMENTS AND PROJECTS

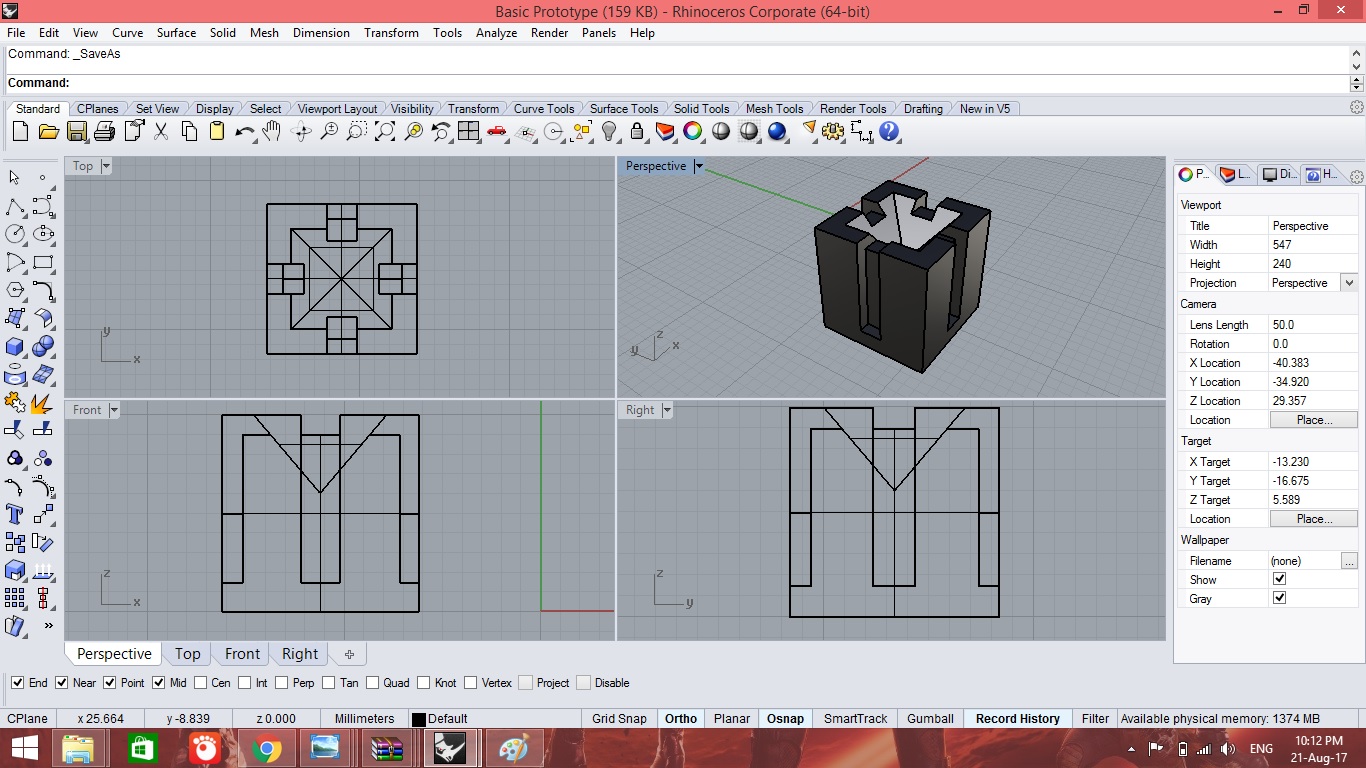

BASIC PROTOTYPE

-

STEP 1: Designing the model

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

-

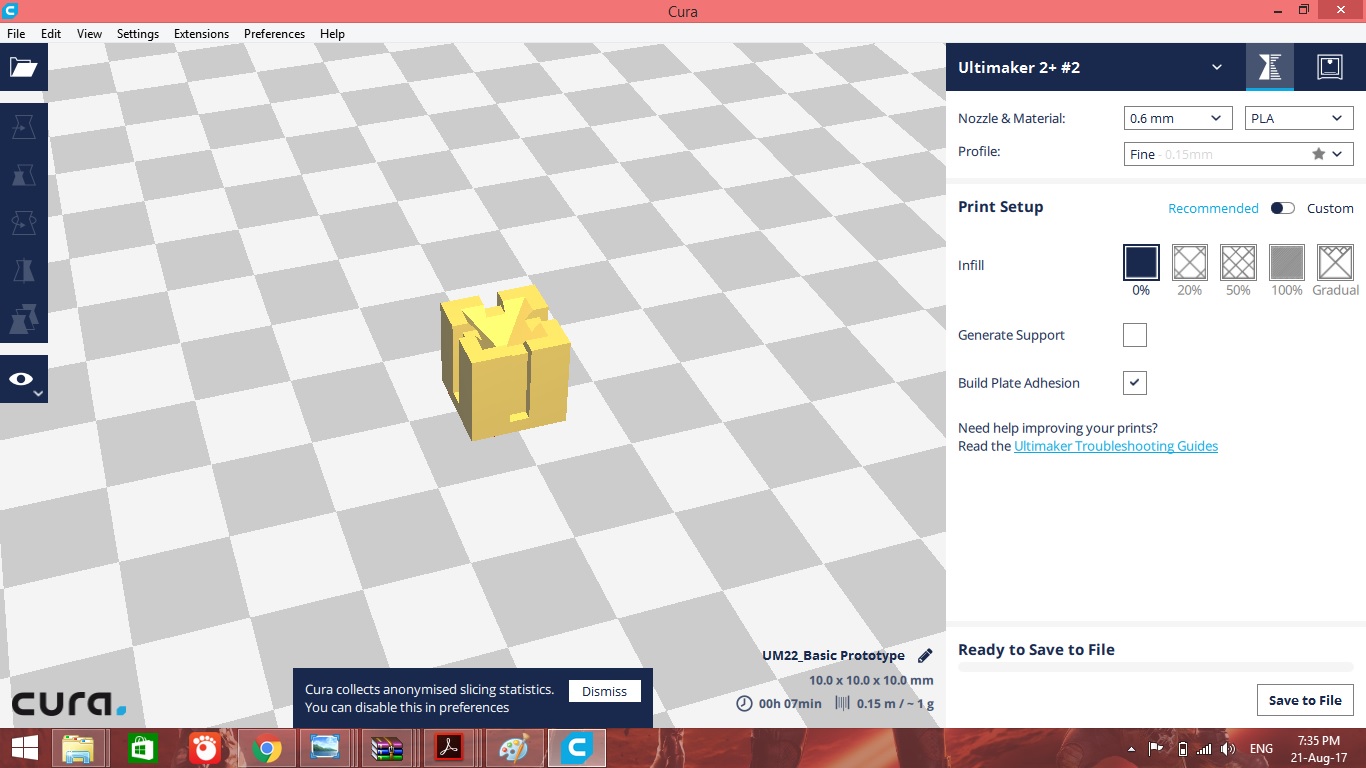

STEP 2: Transfer to Cura

The .3dm file is converted to .stl fil to be edited in Cura software, for adding support structure, analysing dimensions and build time.

The design file in .stl format is available here.

-

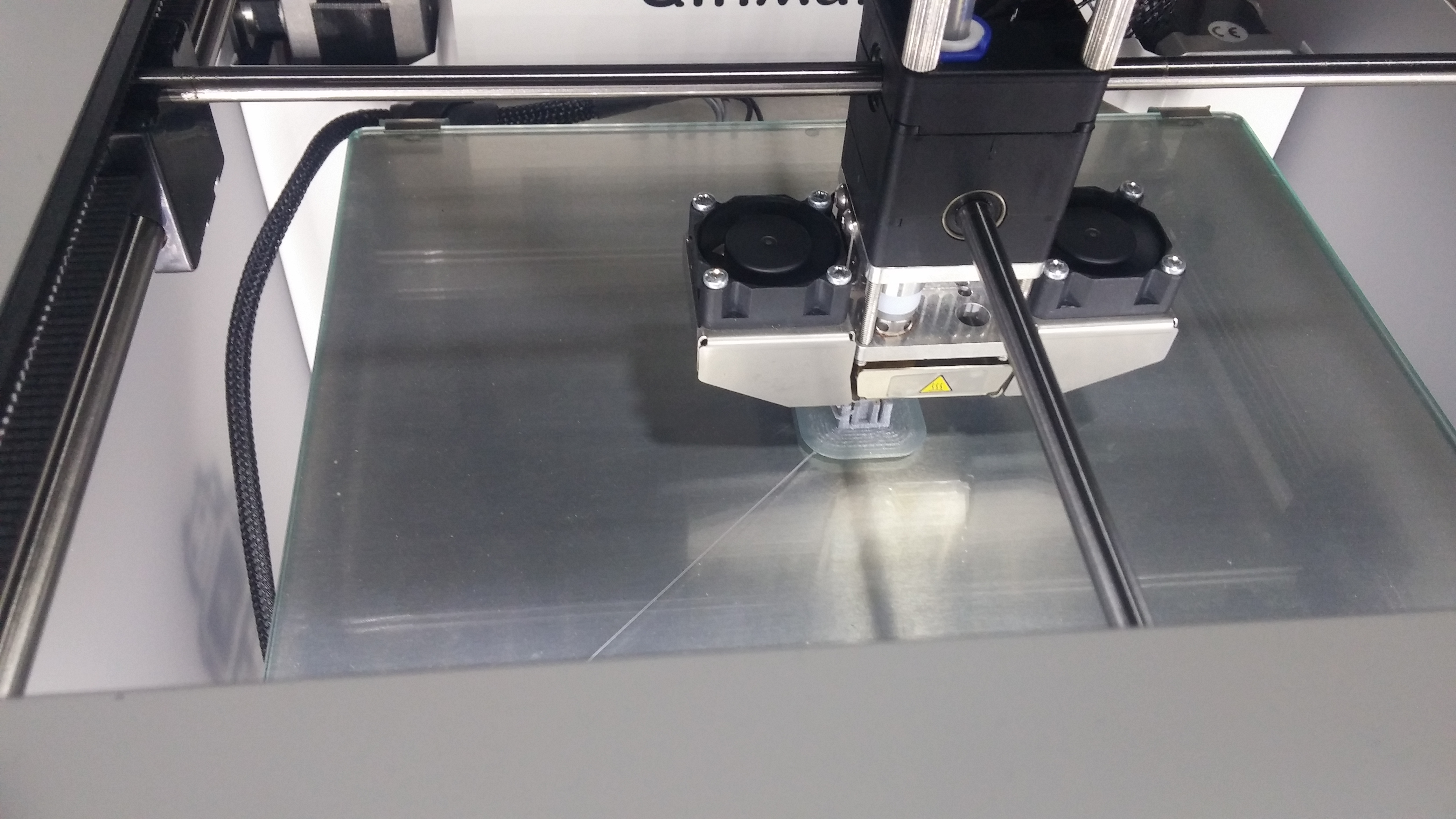

STEP 3: Printing using Ultimaker 2+

The prototype is 3D printed from the design file using Ultimaker 2+ printer.

-

COMPLETED MODEL

After a print time of , the the printed model is taken from the printer plte giving time to cool.

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

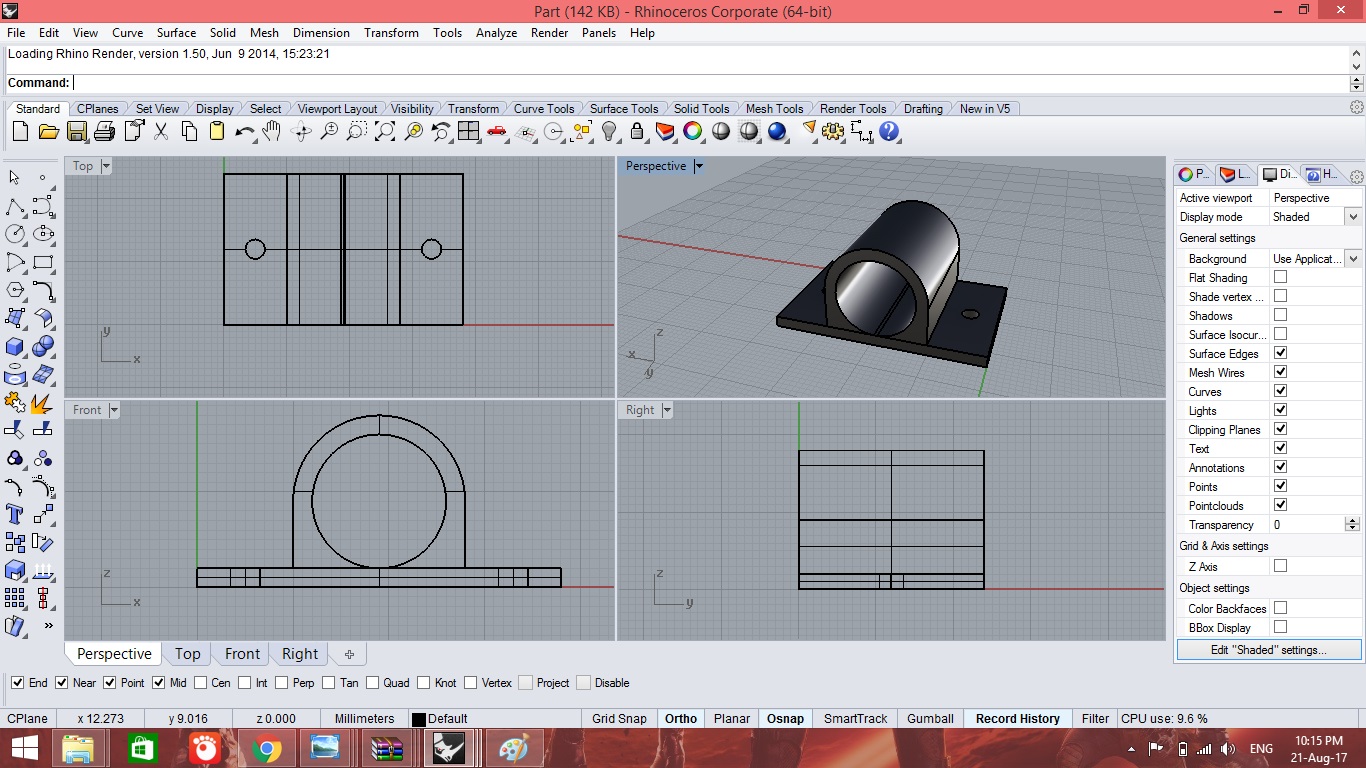

DOOR LOCK SUPPORT

-

STEP 1: Designing the model

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

-

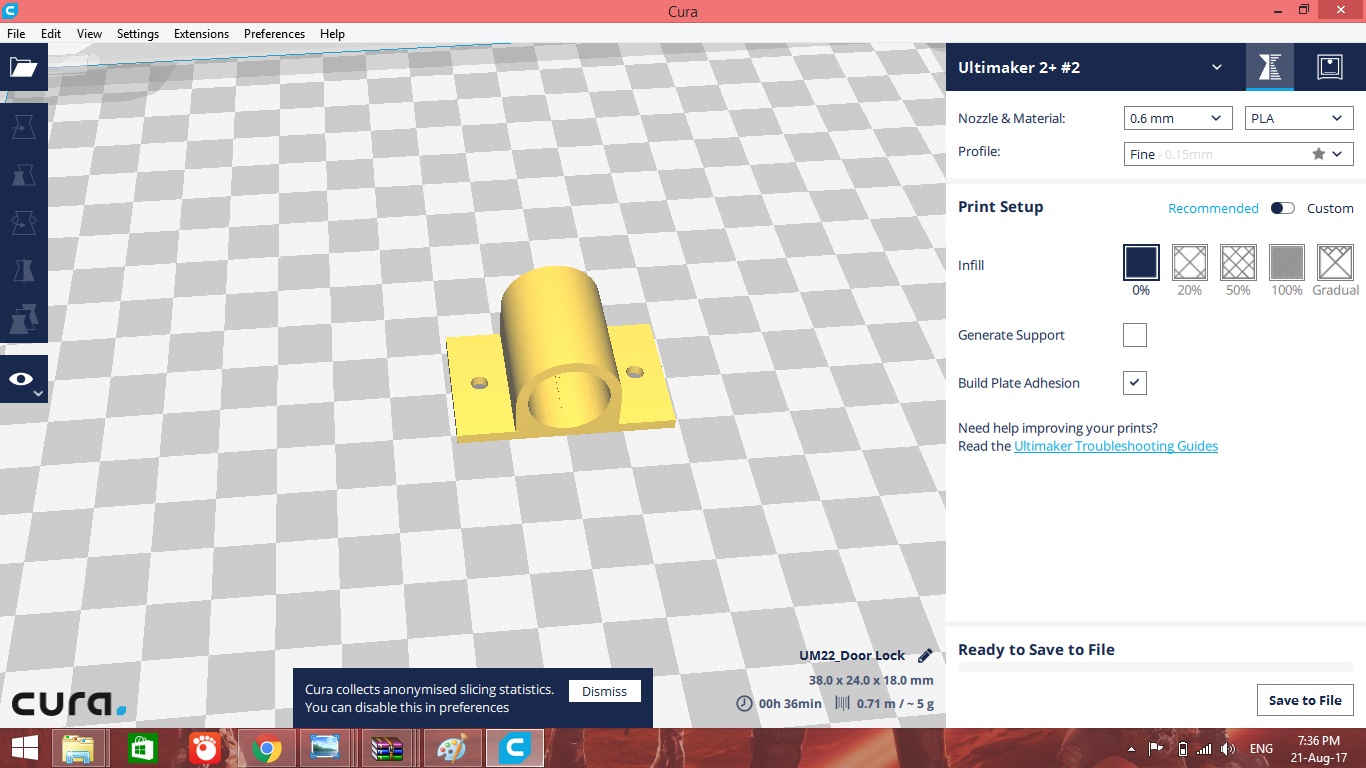

STEP 2: Transfer to Cura

The .3dm file is converted to .stl fil to be edited in Cura software, for adding support structure, analysing dimensions and build time.

The design file in .stl format is aailable here.

-

STEP 3: Printing using Ultimaker 2+

The prototype is 3D printed from the design file using Ultimaker 2+ printer.

-

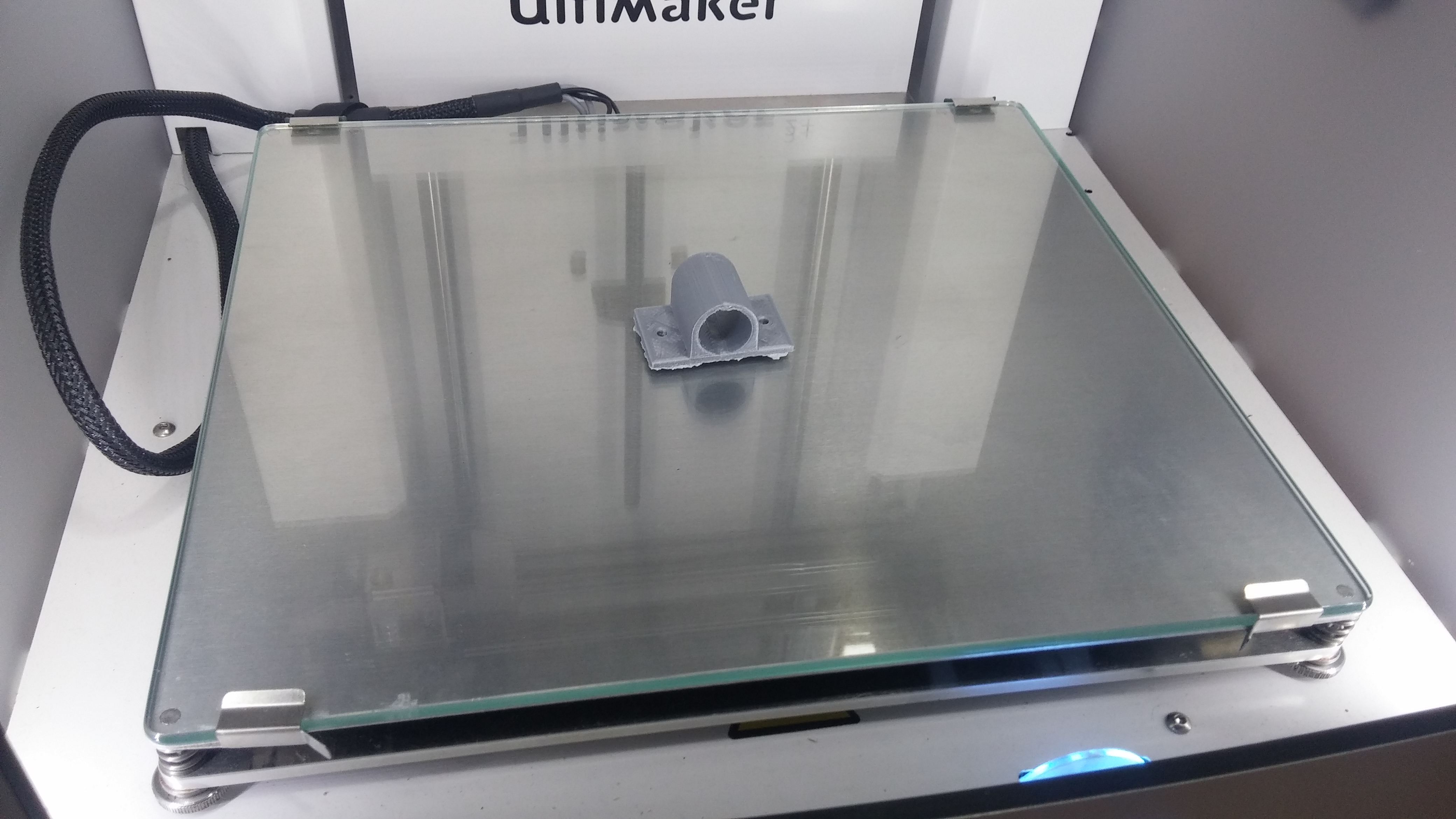

COMPLETED MODEL

After a print time of 18 minutes, the the printed model is taken from the printer plte giving time to cool.

GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS

GO TO HOMEPAGE

GO TO HOMEPAGE

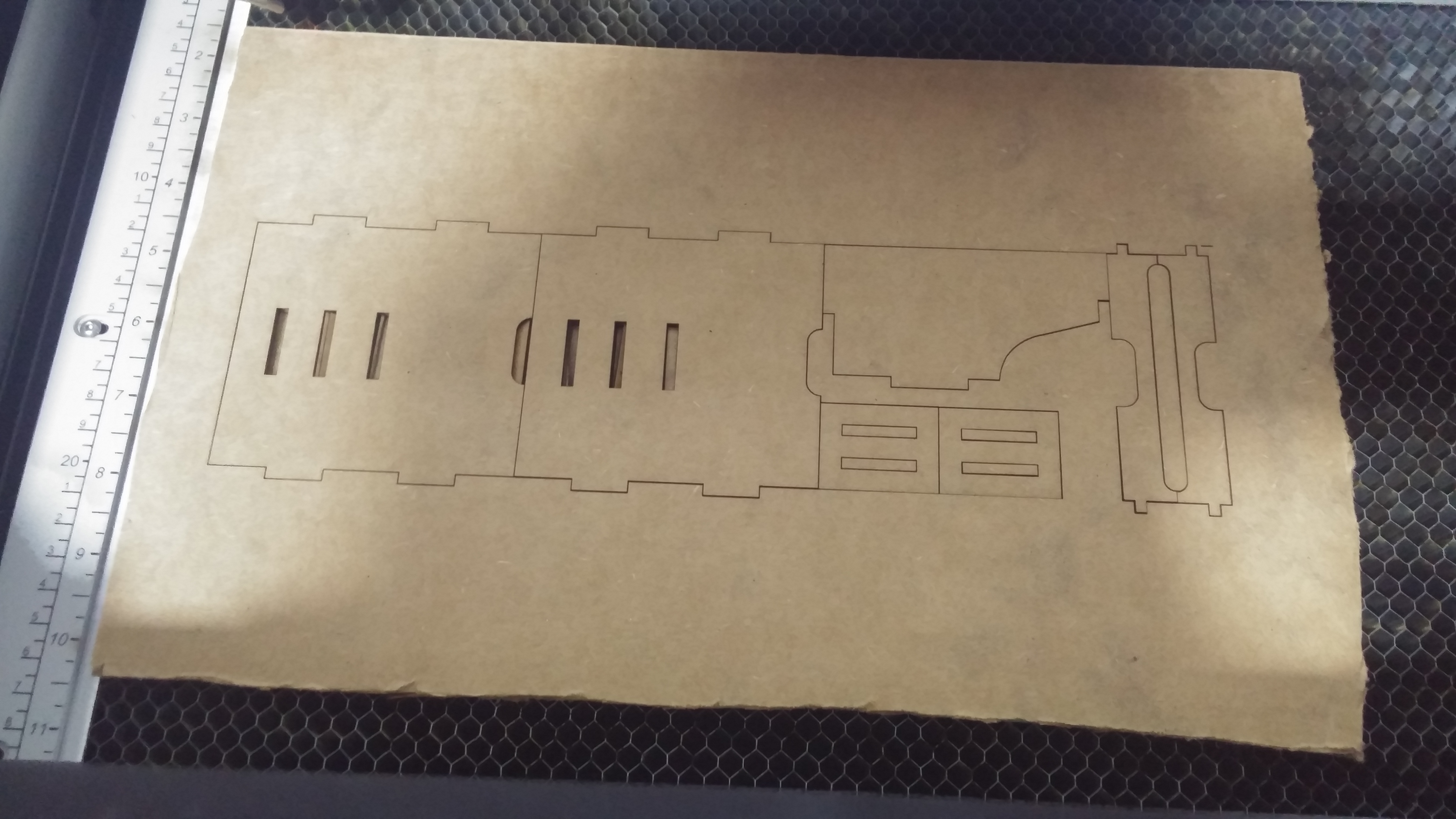

SMARTPHONE STAND

-

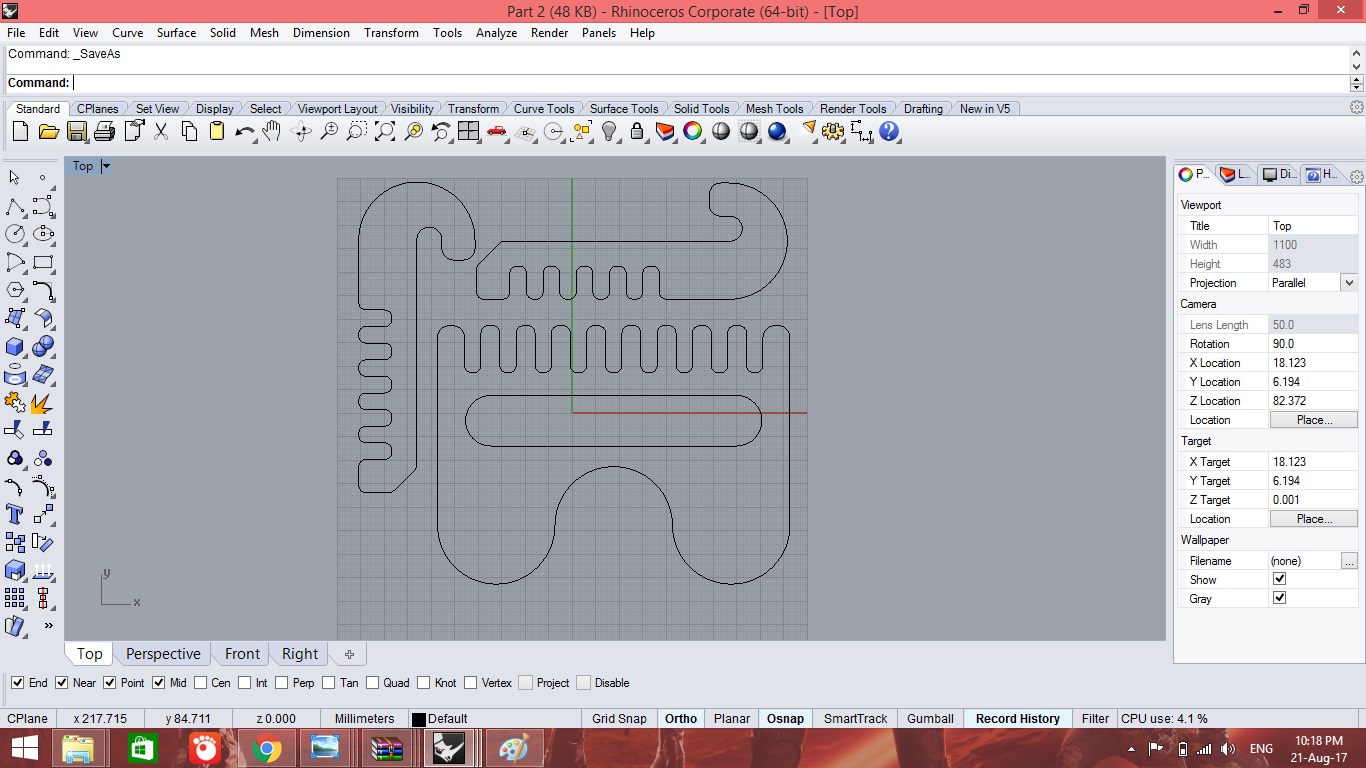

STEP 1: Designing the model

The 2D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

-

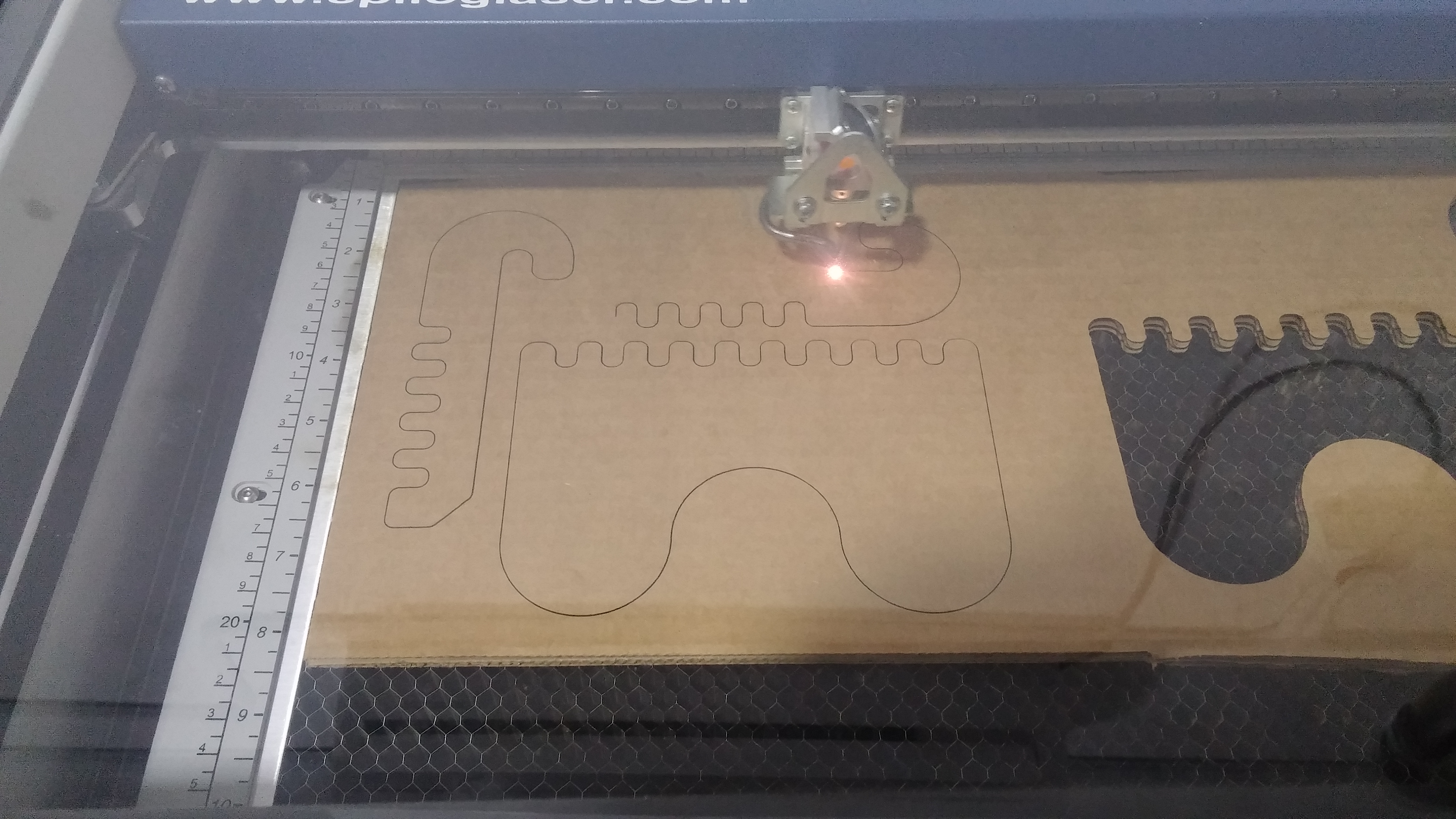

STEP 2: Cutting using Laser cutter

The .3dm file is printed using the laser cutter on a 6mm thick cardboard under 100% power. After an approximate cut time of 2 minutes, the cut piece of the protoype was obtained.

-

STEP 3: Assembly

The prototype is assebmled manually.

-

COMPLETED MODEL

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

BTS LOGO STICKER

-

STEP 1: Designing the model

The 2D design of the model was developed using CutStudio.

-

STEP 2: Cutting using Vinyl cutter

The cutstudio file is printed usiing the vinyl cutter on a 15mm X 15mm vinyl sheet piece. After an approximate cut time of 30 seconds, the cut piece of the protoype was obtained.

-

STEP 3: Pasting

The prototype is pated on laptop surface manually.

-

COMPLETED MODEL

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

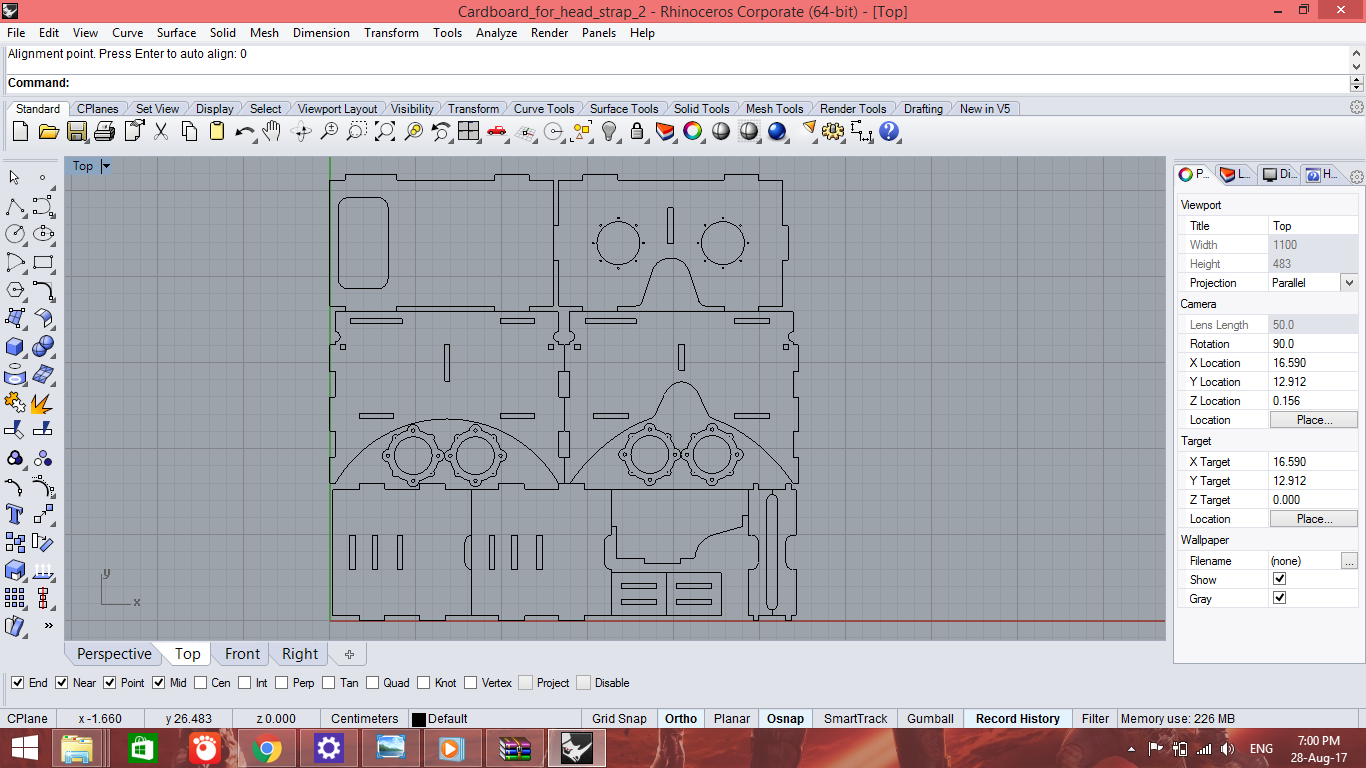

GOOGLE CARDBOARD

-

STEP 1: Designing the model

The 2D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

-

STEP 2: Cutting using Laser cutter

The .3dm file is printed usiing the laser cutter on a 6mm thick cardboard under 100% power. After an approximate cut time of 2 minutes, the cut piece of the protoype was obtained.

-

STEP 3: Assembly

The prototype is assembled manually.

-

COMPLETED MODEL

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

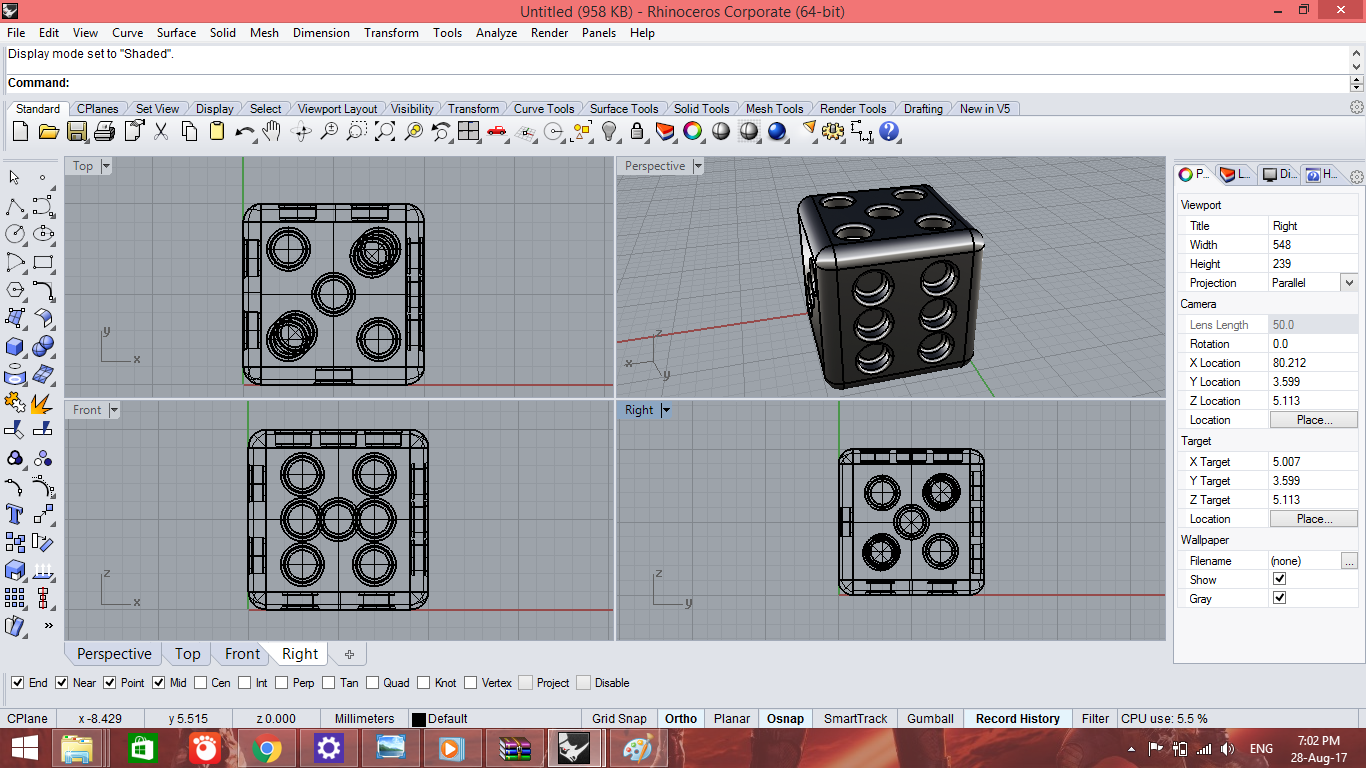

6 FACED DIE

-

STEP 1: Designing the model

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

-

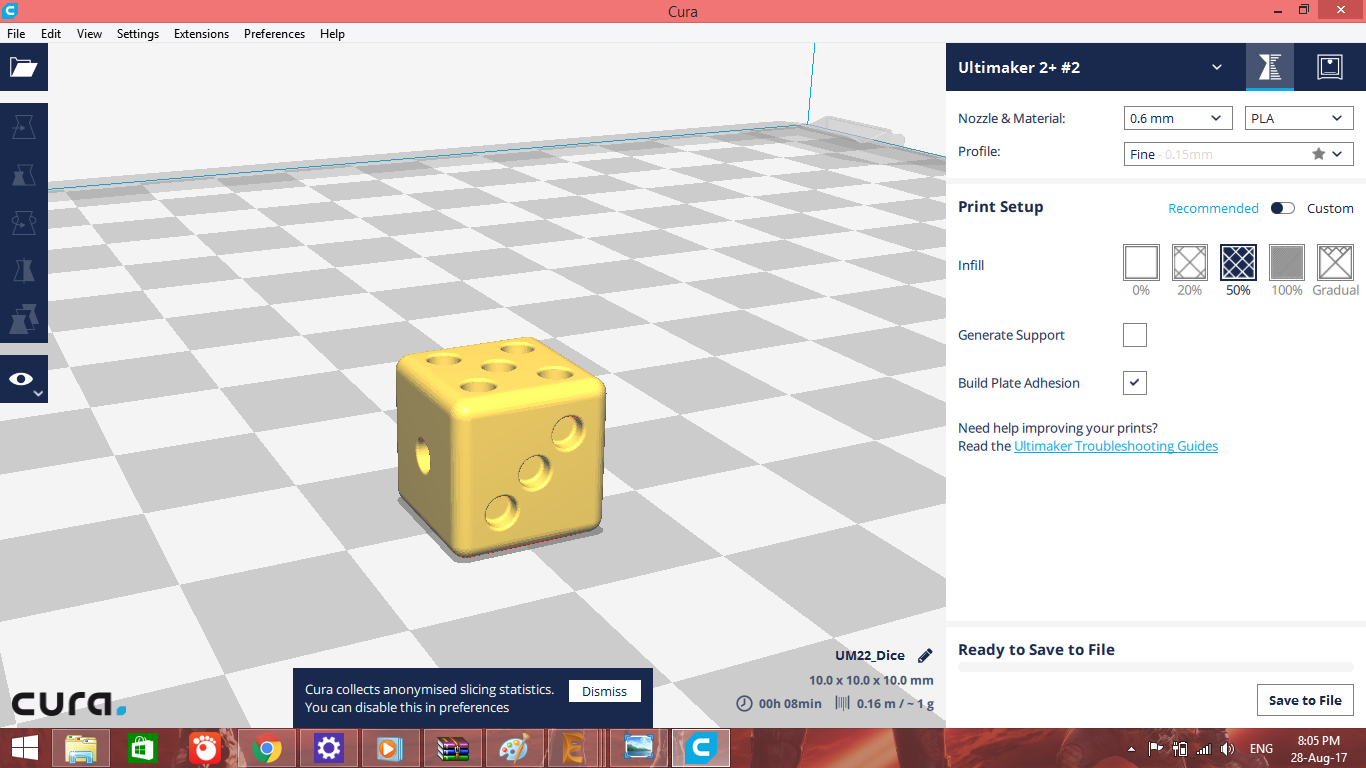

STEP 2: Transfer to Cura

The .3dm file is converted to .stl fil to be edited in Cura software, for adding support structure, analysing dimensions and build time.

The design file in .stl format is aailable here.

-

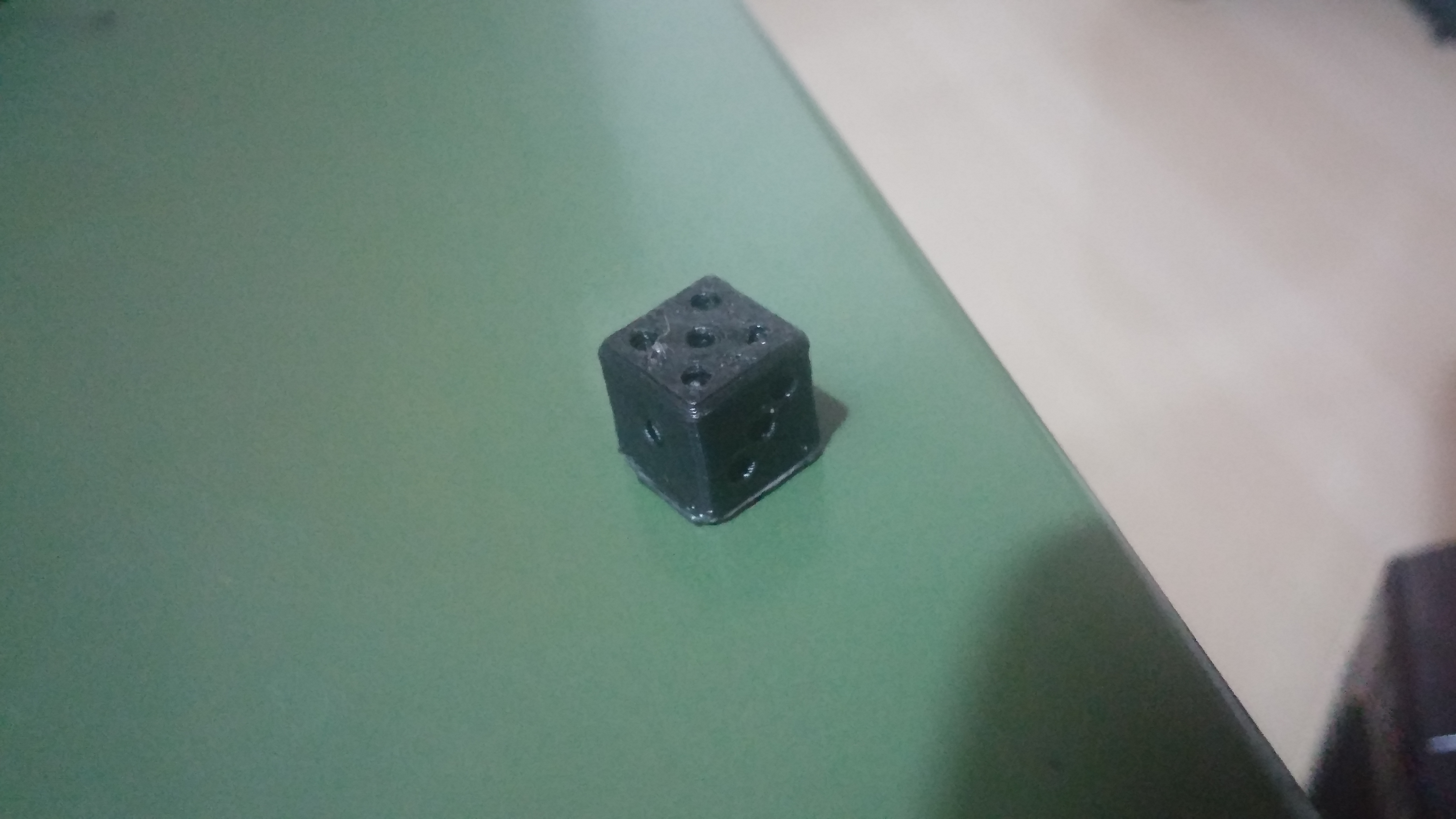

STEP 3: Printing using Ultimaker 2+

The prototype is 3D printed from the design file using Ultimaker 2+ printer.

-

COMPLETED MODEL

After a print time of 8 minutes, the the printed model is taken from the printer plte giving time to cool.

GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS

GO TO HOMEPAGE

GO TO HOMEPAGE

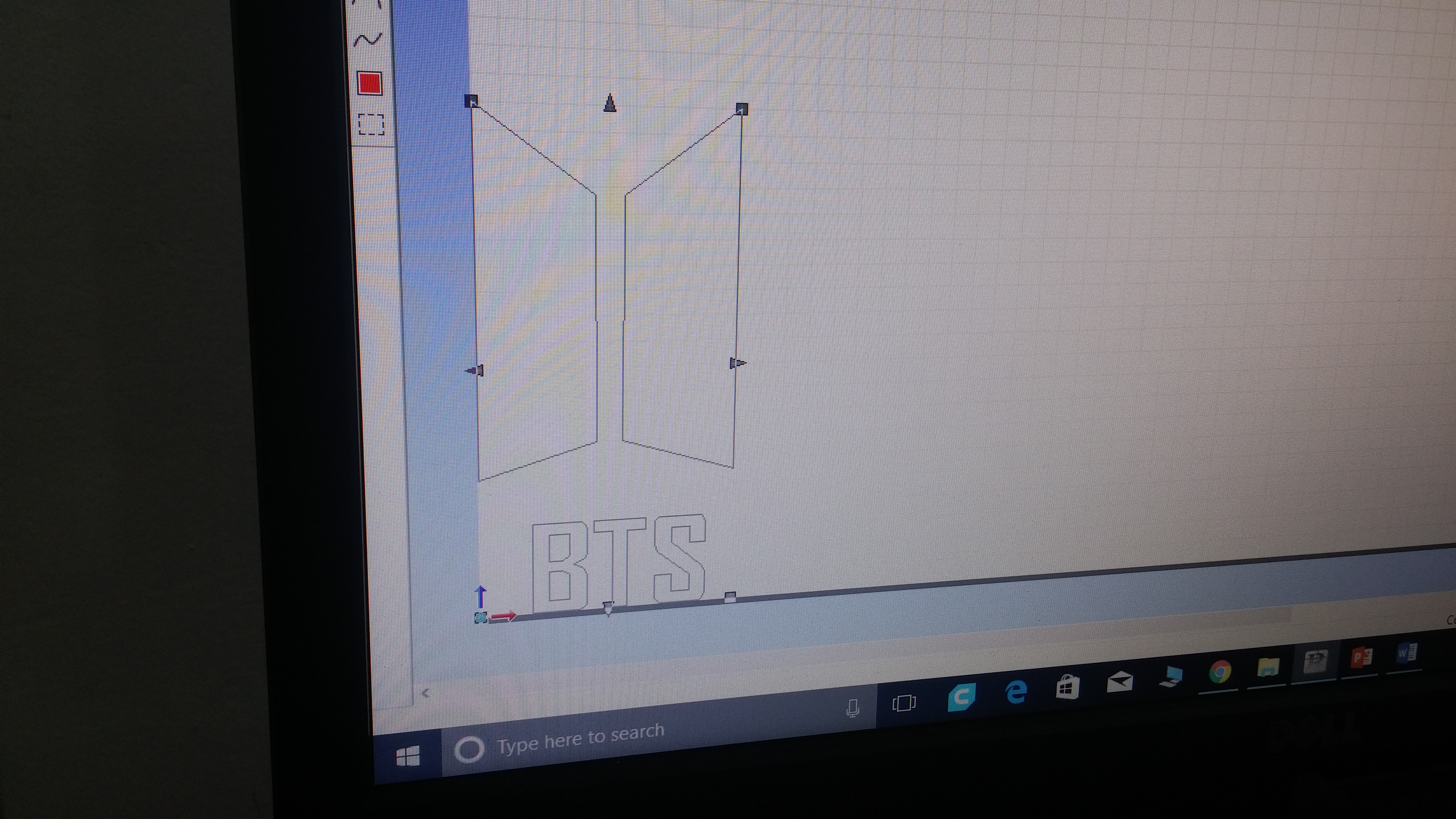

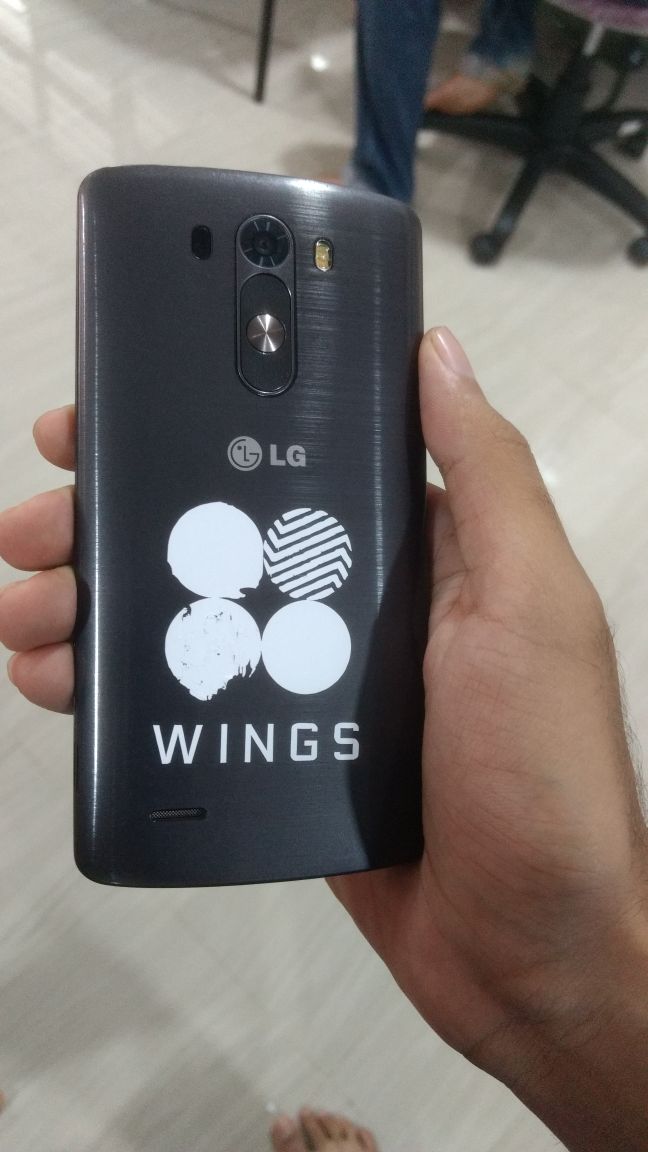

WINGS LOGO

-

STEP 1: Designing the model

The 2D design of the model was developed using CutStudio.

-

STEP 2: Cutting using Vinyl cutter

The cutstudio file is printed usiing the vinyl cutter on a 15mm X 15mm vinyl sheet piece. After an approximate cut time of 30 seconds, the cut piece of the protoype was obtained.

-

STEP 3: Pasting

The prototype is pated on laptop surface manually.

-

COMPLETED MODEL

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

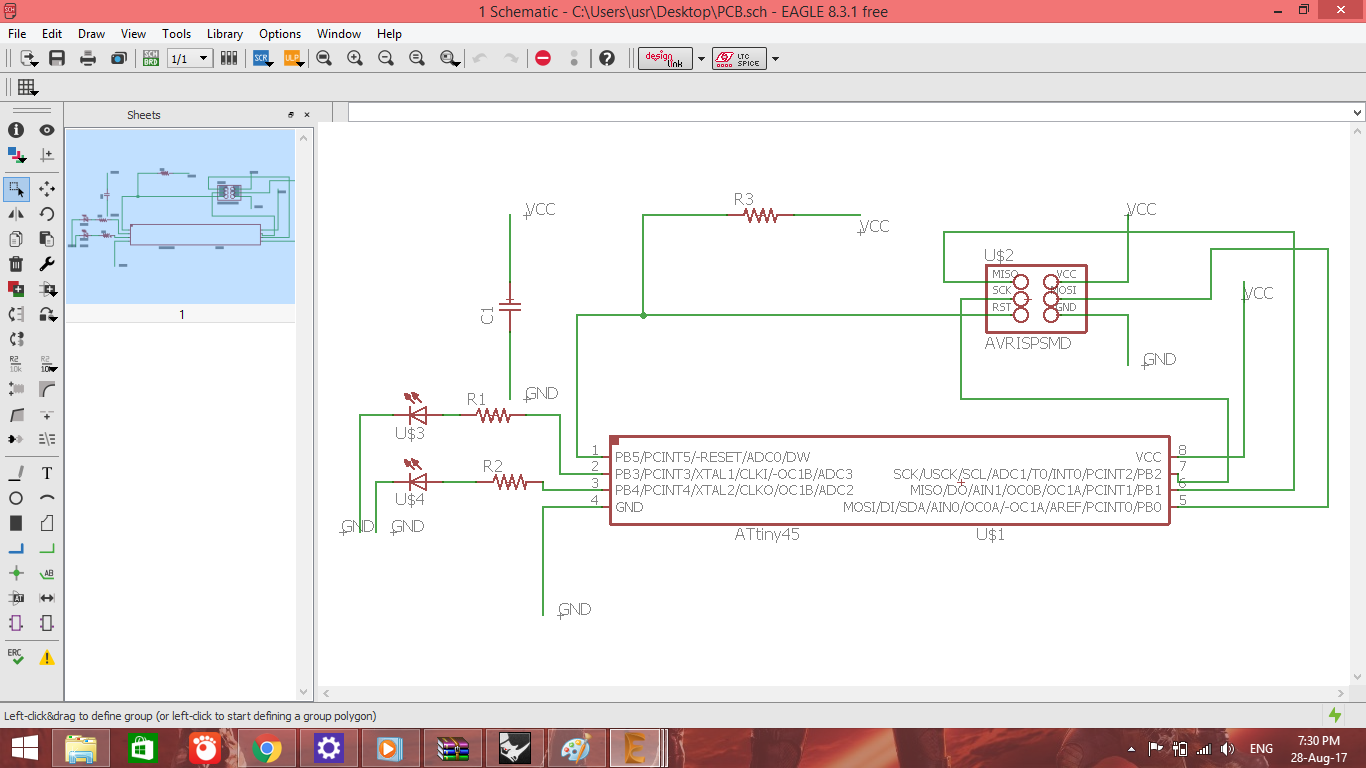

PCB CIRCUIT

-

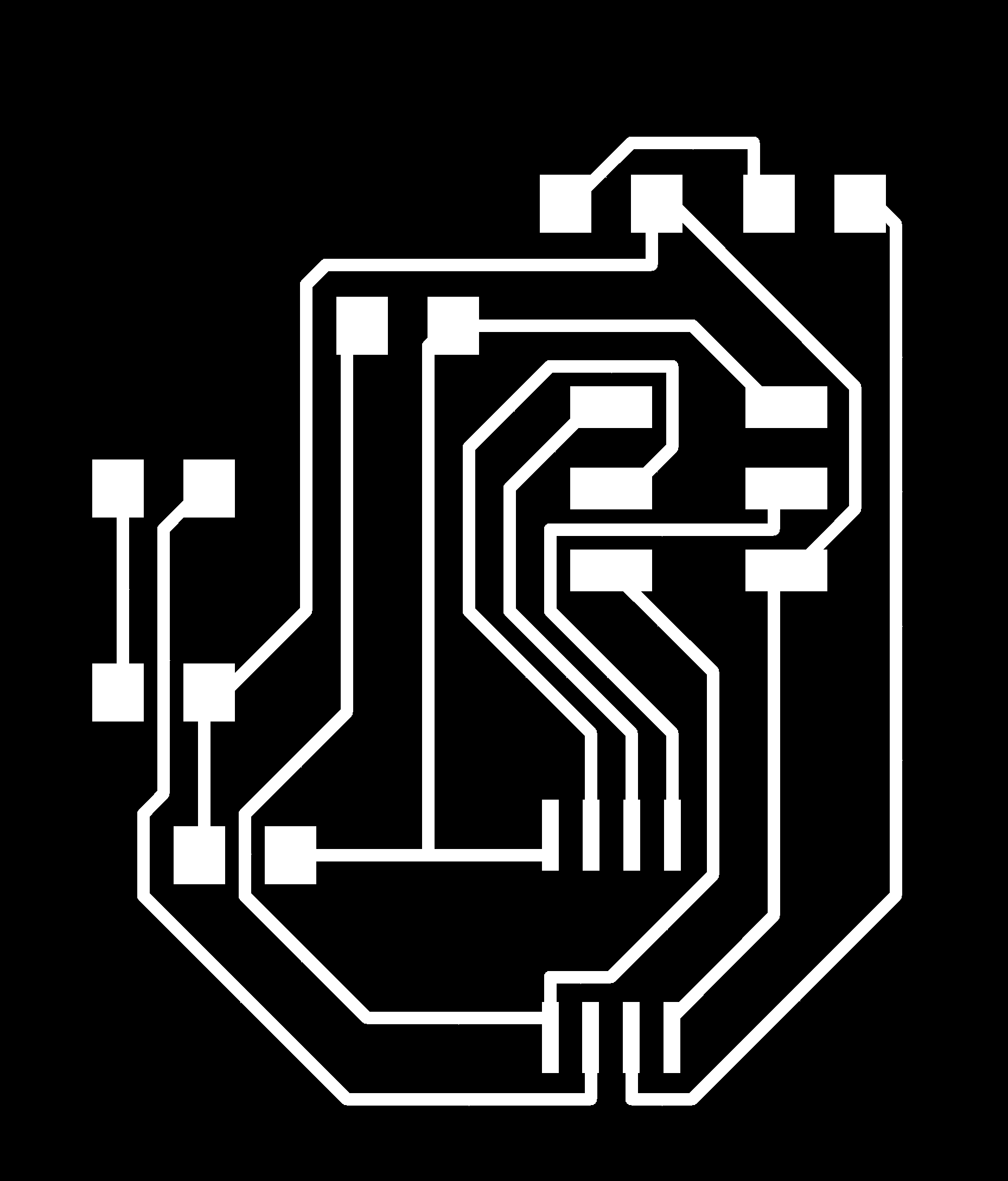

STEP 1: Designing the model

The 2D design of the model was developed using Autodesk Eagle.

The .sch file of the schematics is available here.

The .brd file of the board is available here.

-

STEP 2: Autorouting using Eagle

THe designed circuit is routed using the autoroute feature in Autodesk Eagle

-

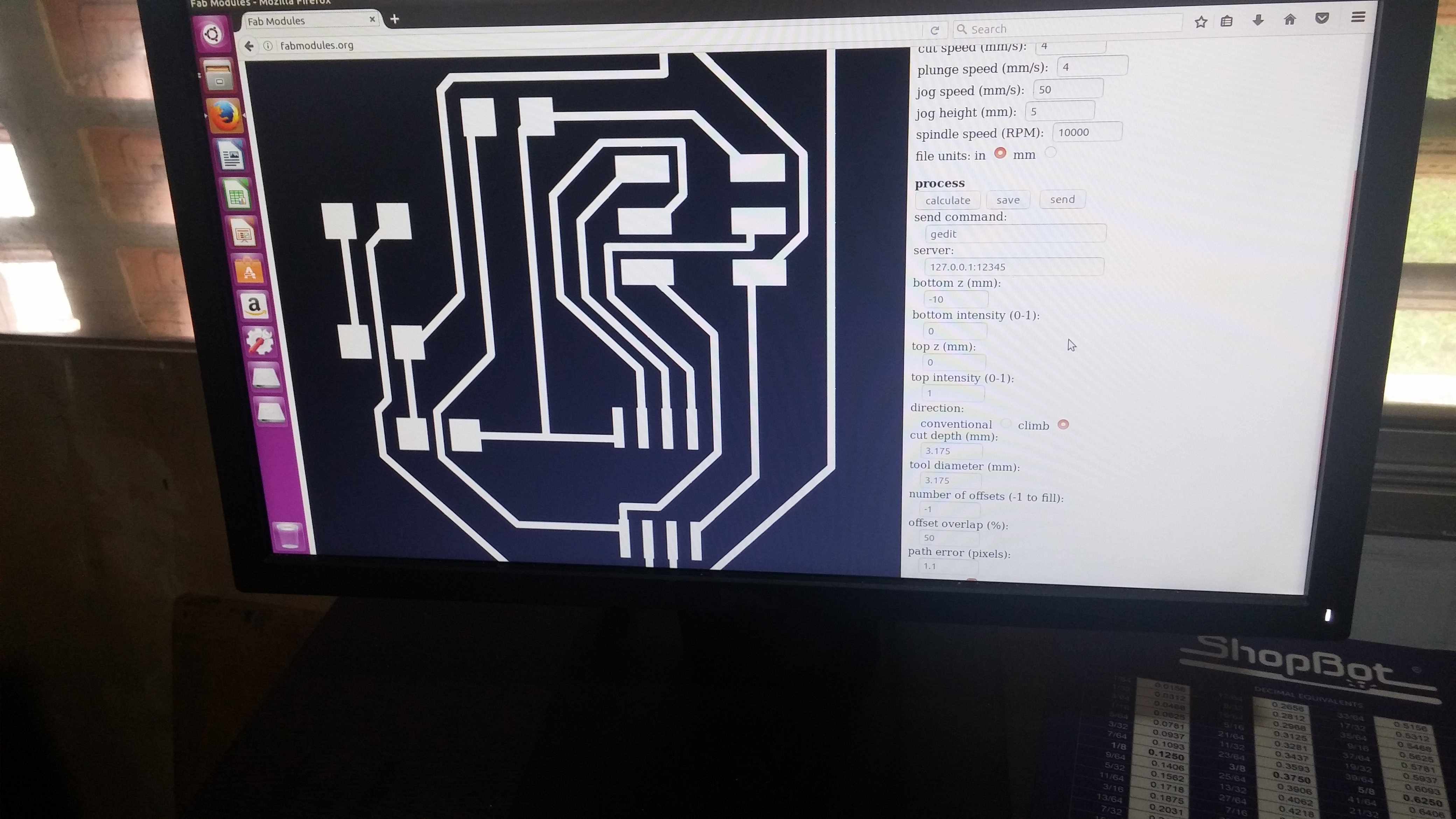

STEP 3: Processing using fabmodules.org

The .png format of Trace is uploaded to fabmodules.org and procesed with desired values

-

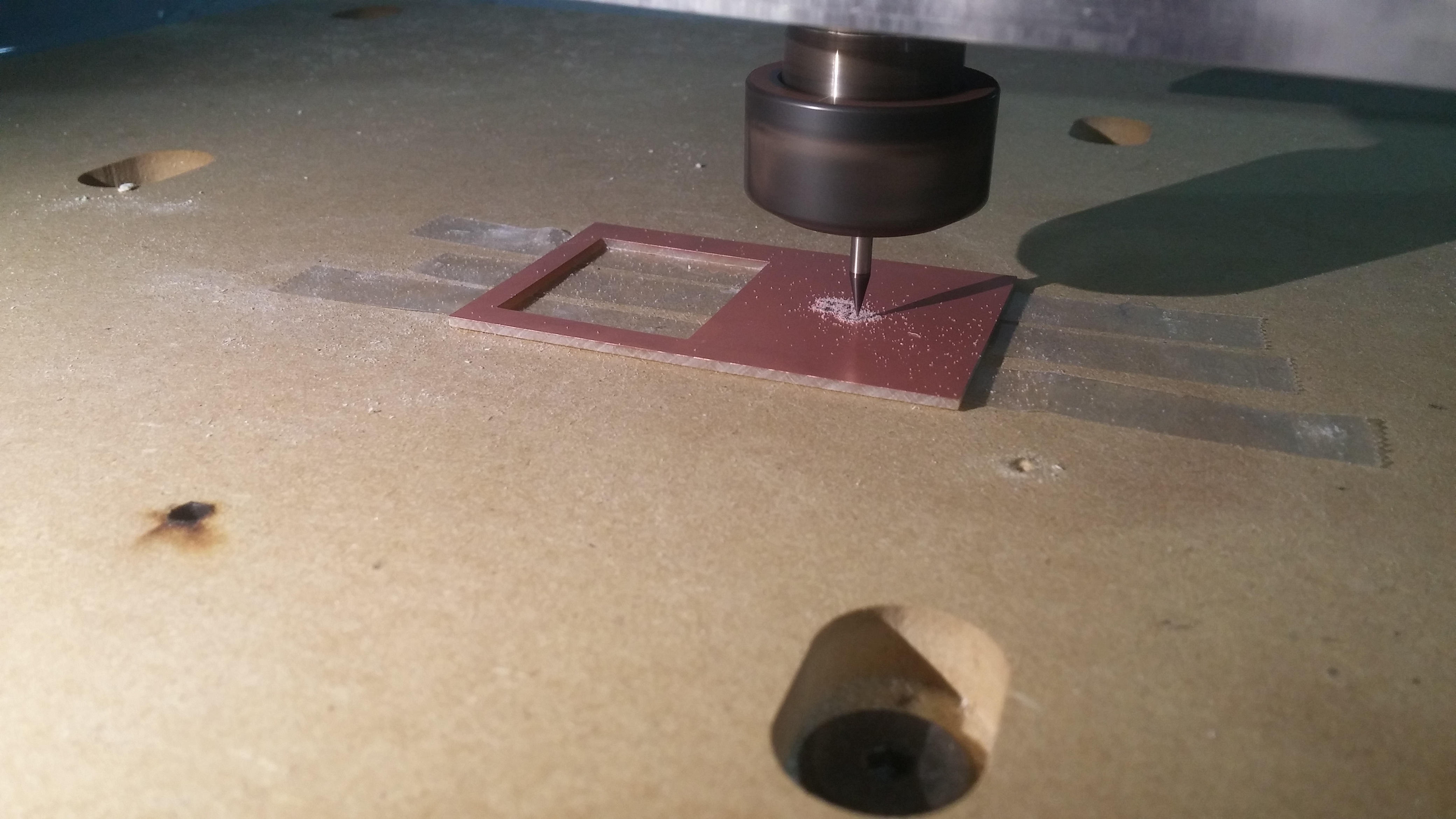

STEP 4: Milling using ShopBot CNC

The processed gcode of the PCB design is milled using Shopbot CNC machine.

-

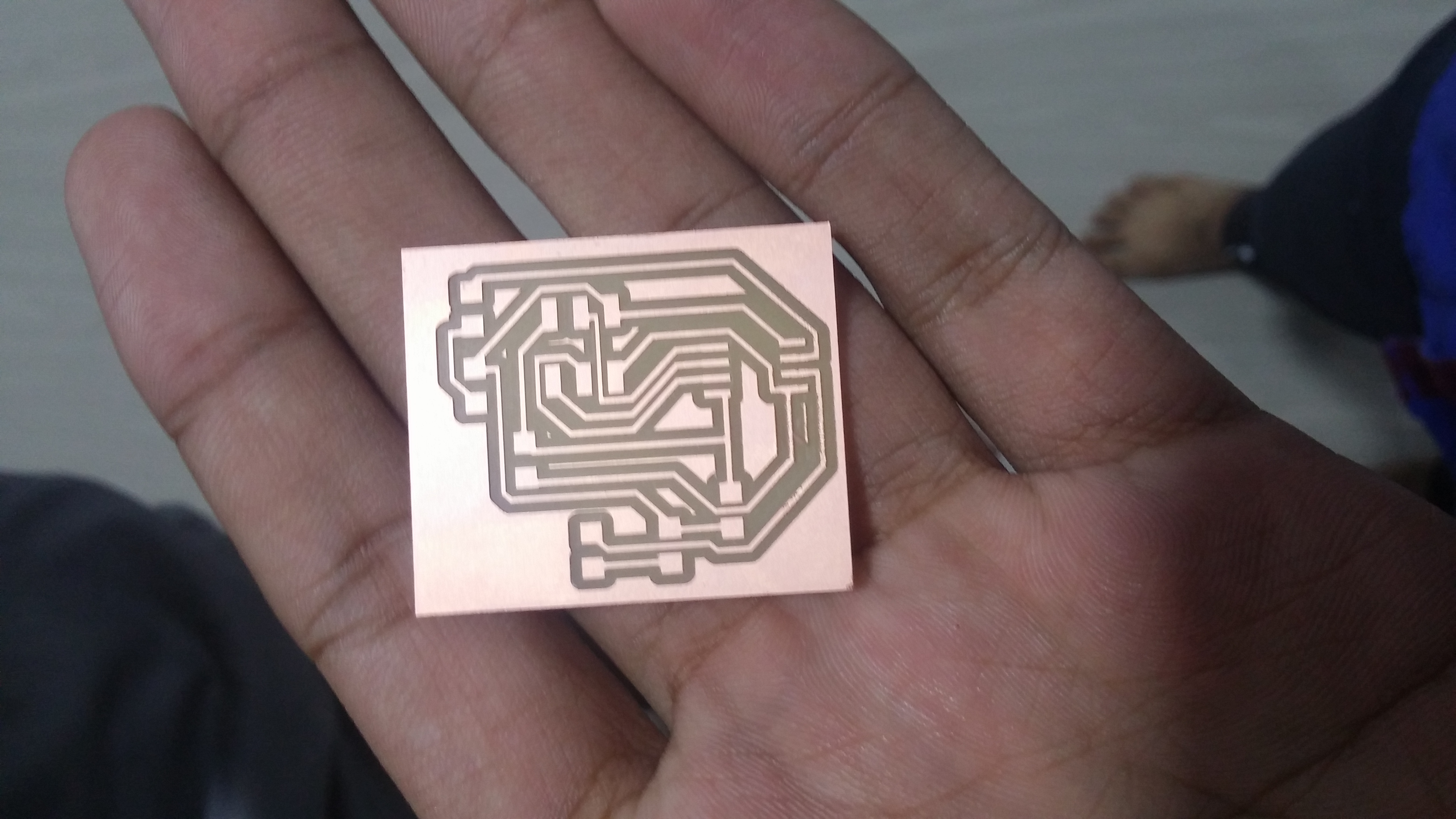

COMPLETED MODEL

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

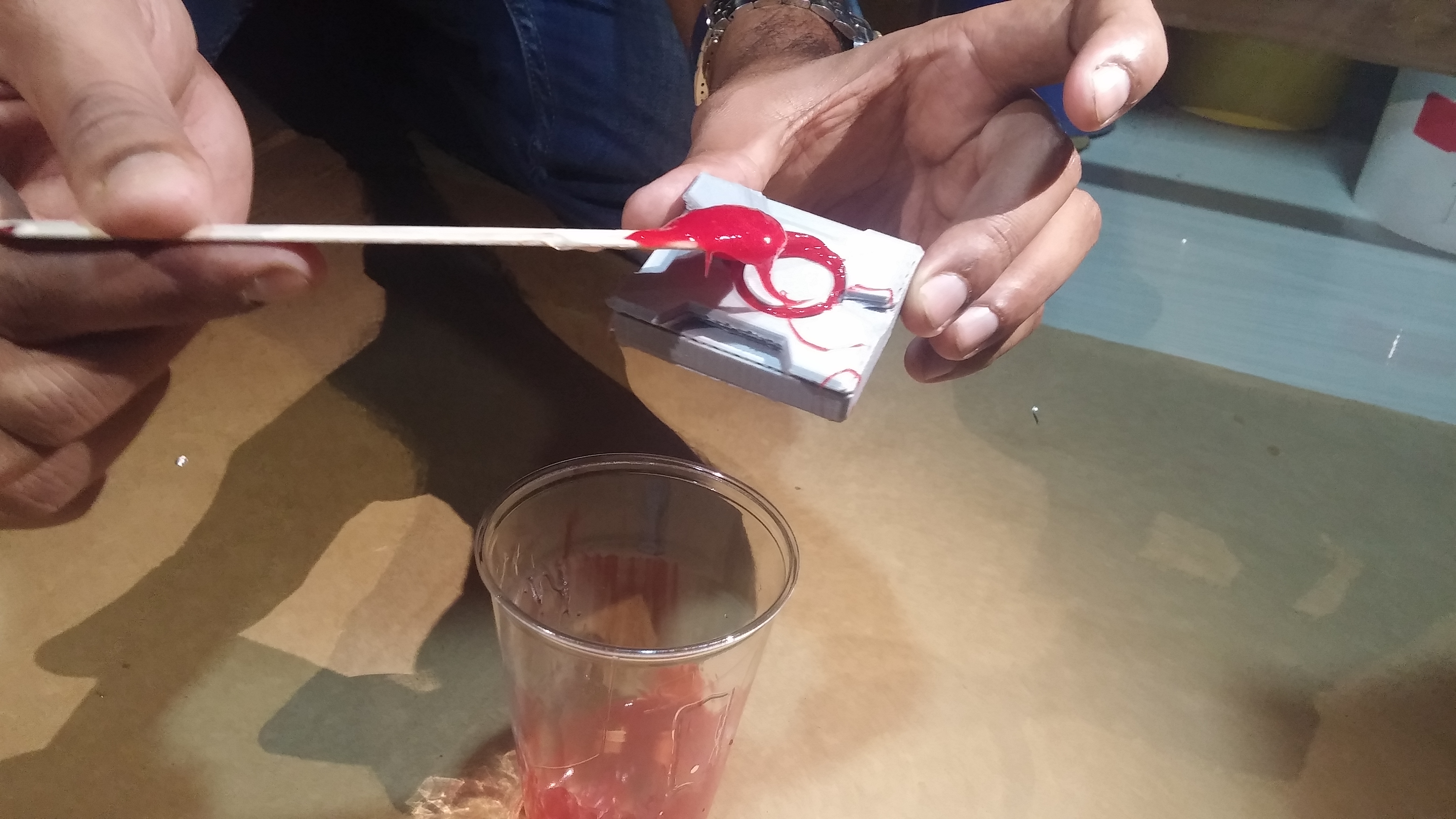

RING MODEL

-

STEP 1: Designing the mould

The 3D Design of the mould was printed using Ultimaker 2+ 3D Printer

-

STEP 2: Mixing the silicone rubber gel

The part A and part B of the silicone gel was mixed together thoroughly and 2 drops of red colour was added.

-

STEP 3: Casting process

THe prepared rubber gel was casted into the mould.

-

STEP 4: Setting

The casted model is ept for setting time of 4 hours.

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

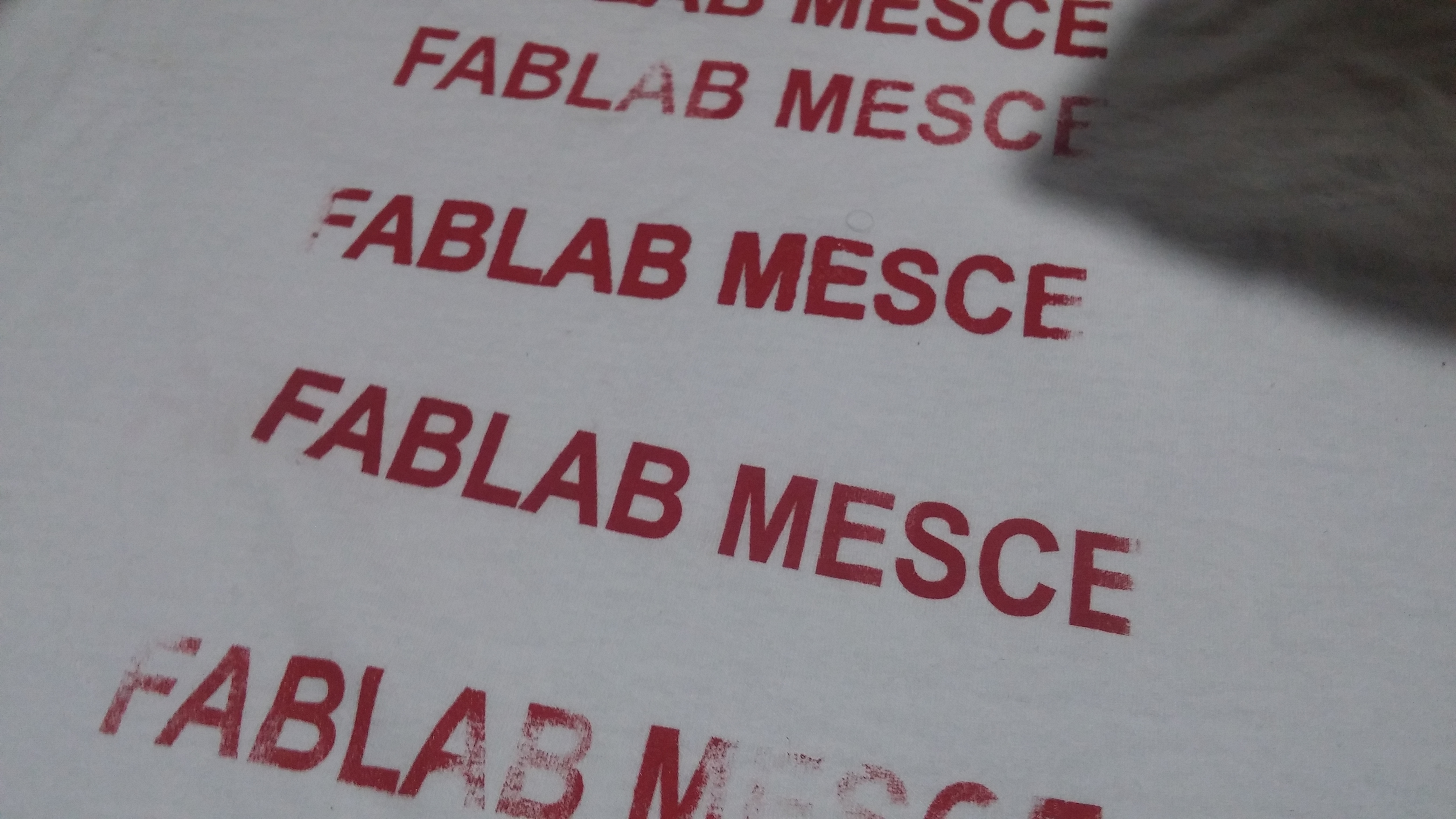

FABLAB T SHIRT

-

STEP 1: Designing the model

The 2D design of the model was developed using CutStudio.

-

STEP 2: Cutting using Vinyl cutter

The cutstudio file is printed usiing the vinyl cutter on a 15mm X 15mm vinyl sheet piece. After an approximate cut time of 30 seconds, the cut piece of the protoype was obtained.

-

STEP 3: Pasting

After creating holes, the stencil is pasted on to the screen

-

STEP 4: Wiping Process

The printing paint was wiped onto the tshirt using printing wiper.

-

COMPLETED MODEL

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

FREE TIME WORKS

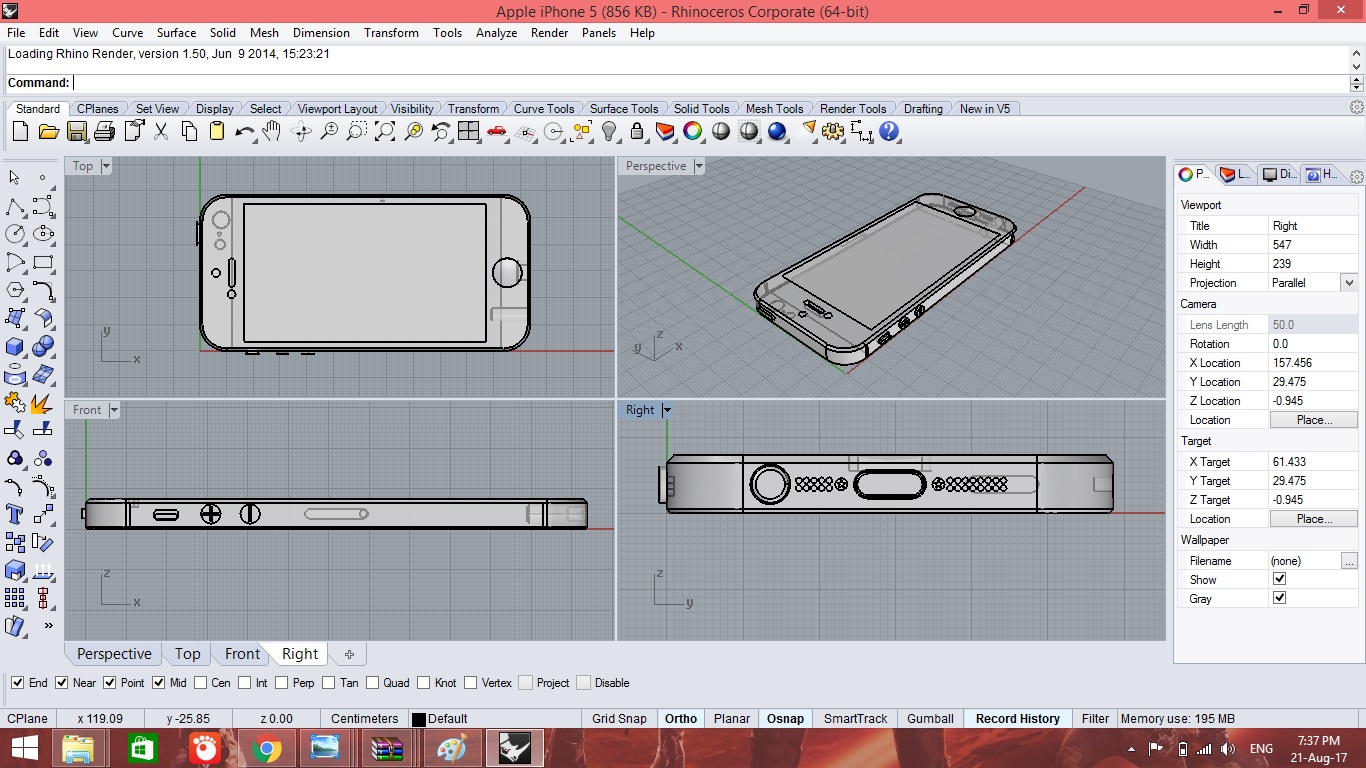

IPHONE 5

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

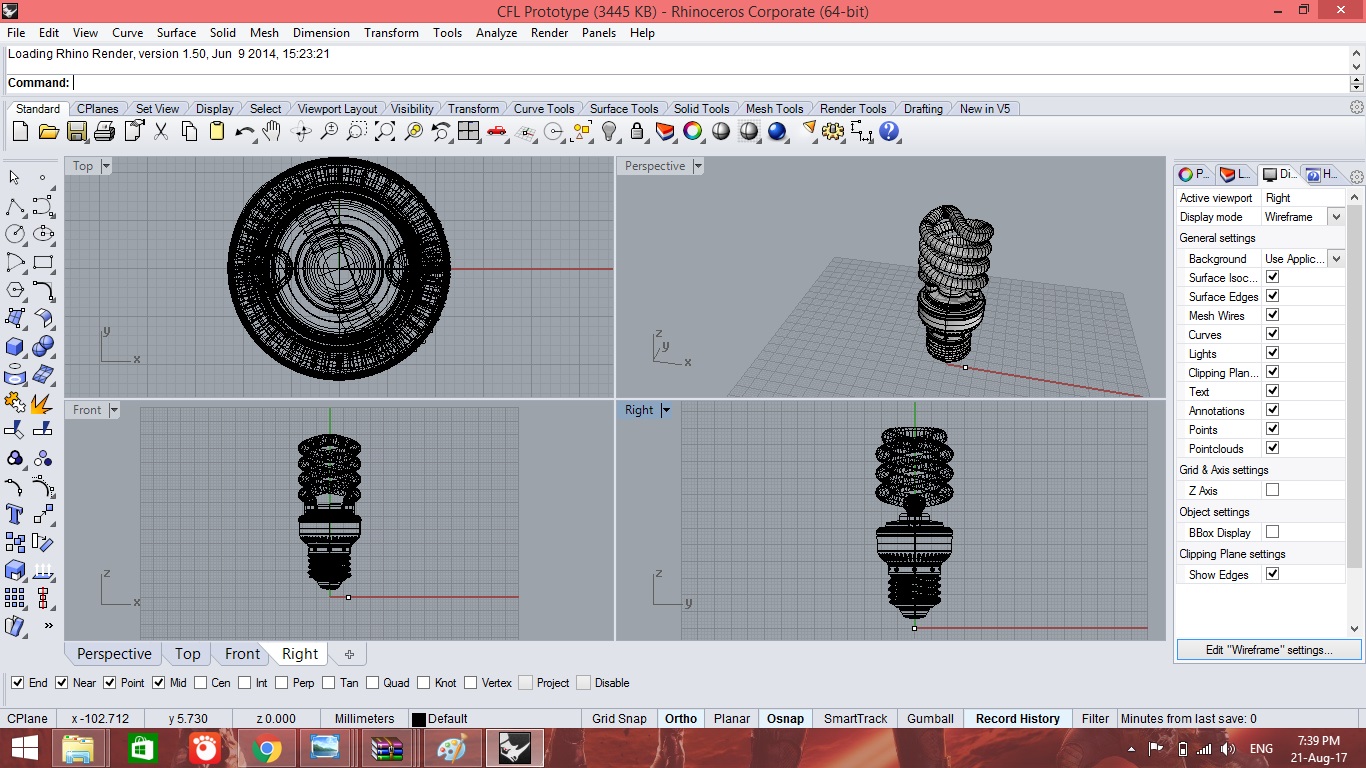

CFL BULB

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

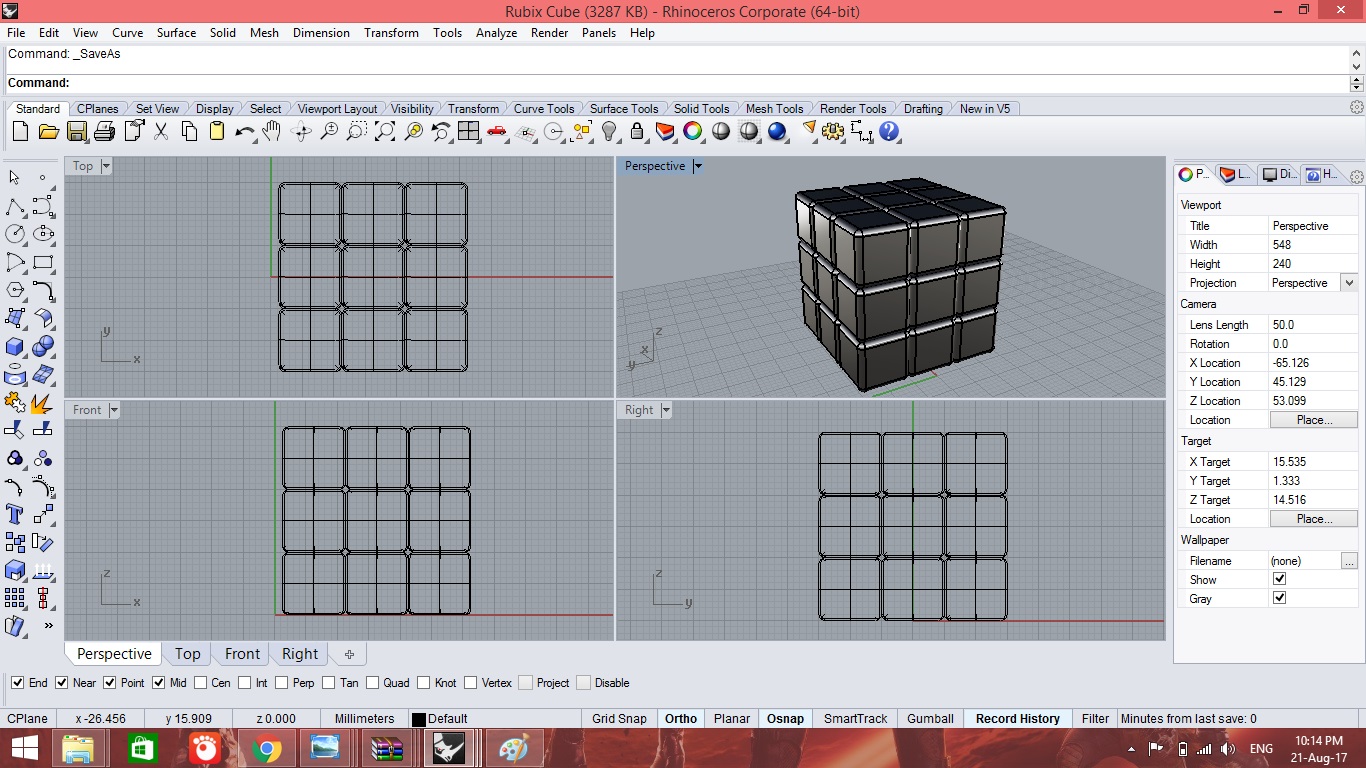

RUBIX CUBE

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

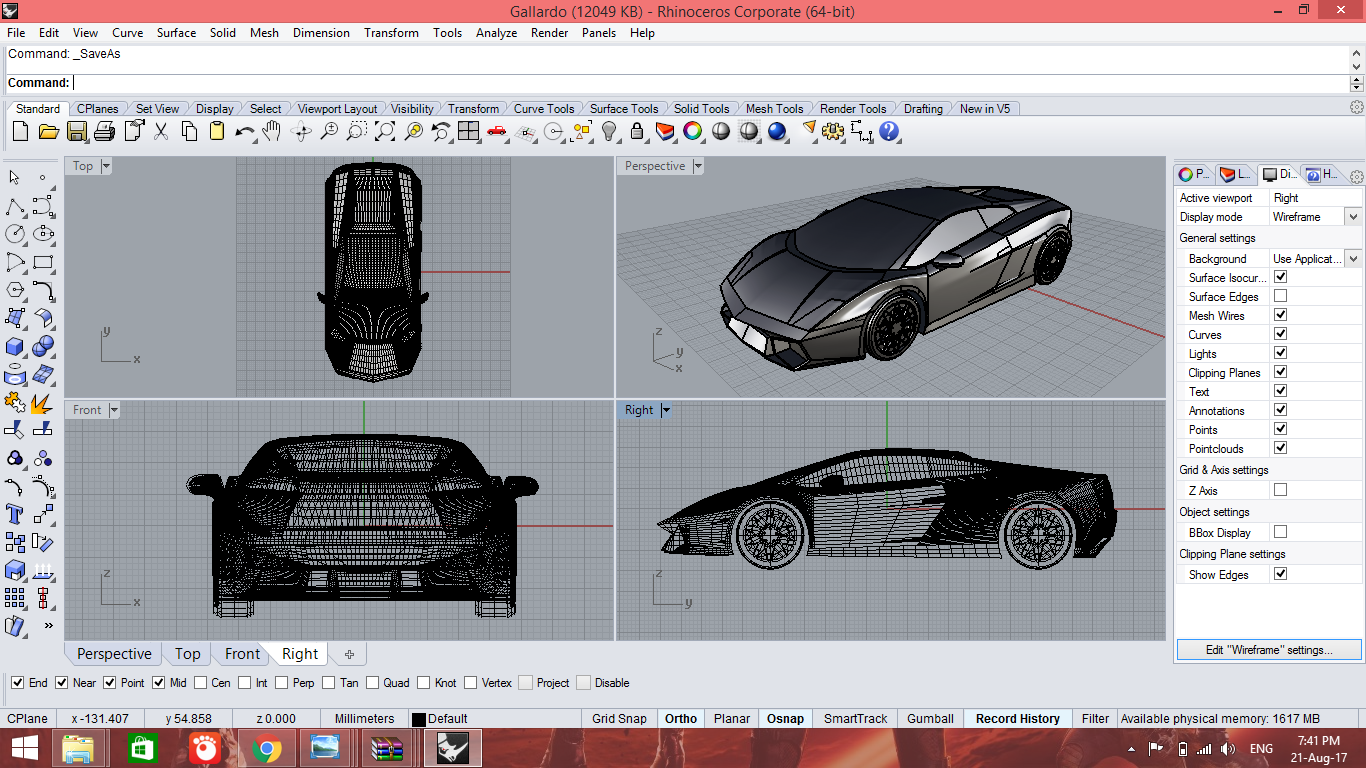

LAMBORGHINI GALLARDO

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.

![]() GO TO SECTIONAL CONTENTS

GO TO SECTIONAL CONTENTS ![]()

![]() GO TO HOMEPAGE

GO TO HOMEPAGE ![]()

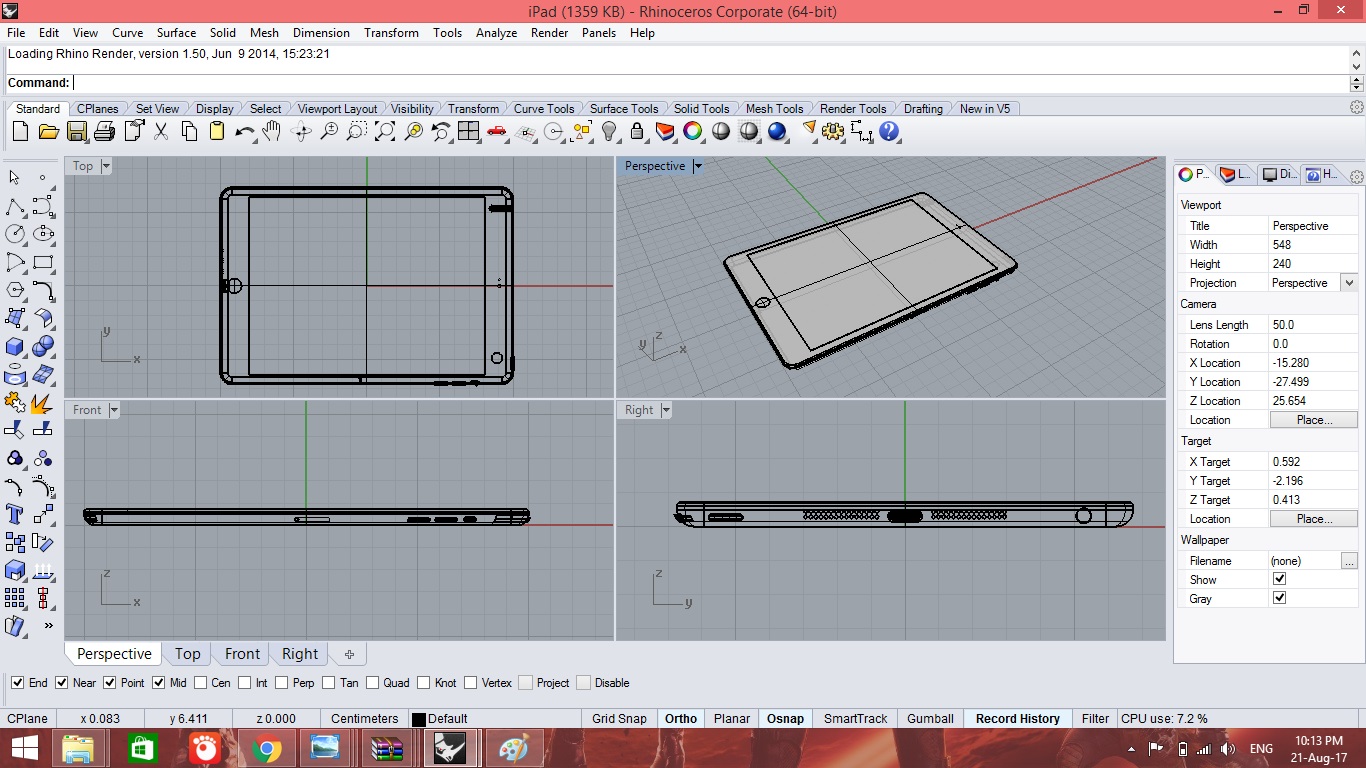

IPAD MINI

The 3D design of the model was developed using Rhinoceros 3D.

The design file in .3dm format is available here.